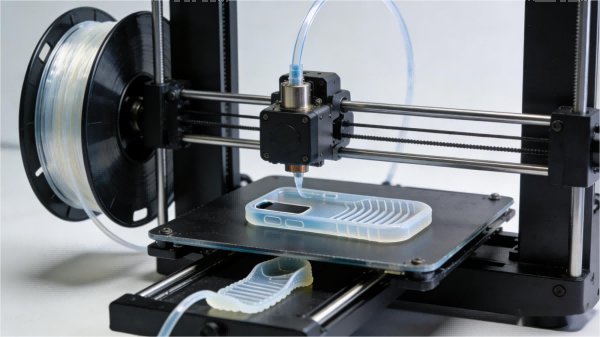

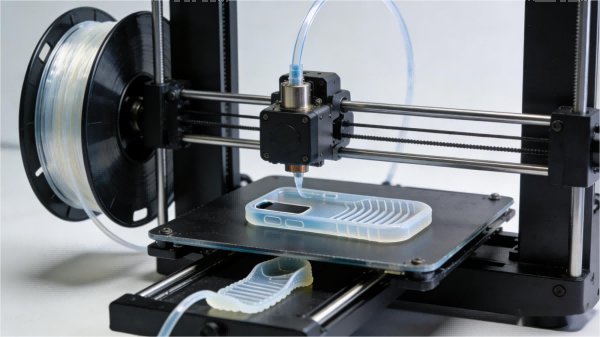

3D Printing: 3D printing, also known as additive manufacturing, builds objects layer by layer using a digital design. It involves melting or curing to create a three-dimensional object.

Traditional Injection Molding: Injection molding is process where molten is injected into a cavity under high pressure. The material then solidifies and takes the shape of the mold.

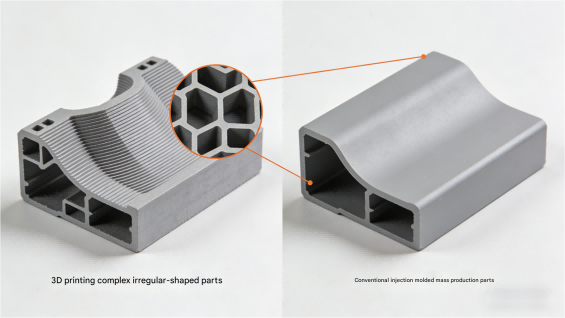

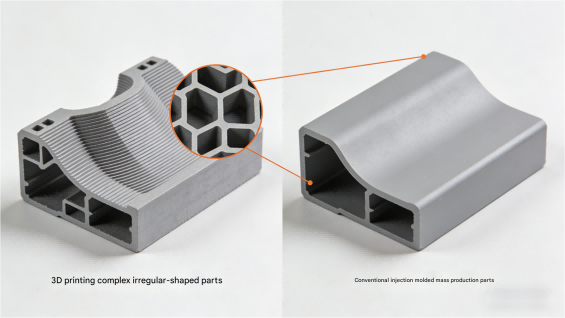

Design Flexibility:

3D Printing: 3D printing allows for complex geometries and intricate designs that are difficult to achieve with traditional manufacturing methods. It offers design freedom and the ability to create customized, unique, and intricate parts.

Traditional Injection Molding: Injection molding is better suited for producing large quantities of identical parts with consistent dimensions. It may have some limitations in terms of design complexity and flexibility compared to 3D printing.

Time and Cost:

3D Printing: 3D printing is well-suited for rapid prototyping and low-volume production. It eliminates the need for expensive molds, reducing upfront costs and lead times. However, it can be slower and more costly for large-scale production compared to traditional injection molding.

Traditional Injection Molding: Injection molding is efficient for high-volume production as it can produce a large number of parts in a shorter time frame. Once the molds are created, the production process becomes faster and more cost-effective for mass production.

Material Selection:

3D Printing: 3D printing supports a wide range of materials, including plastics, metals, composites, ceramics, and more. Different techniques such as FDM, SLA, SLS, and DMLS offer various material options with different properties and characteristics.

Traditional Injection Molding: Traditional injection molding supports a variety of materials, including thermoplastics, thermosetting plastics, elastomers, and more. There is a wide selection of materials available specifically for injection molding, allowing for desired mechanical properties, aesthetics, and performance.

Surface Finish and Quality:

3D Printing: Depending on the 3D printing technology and settings, the surface finish of 3D printed parts may have varying levels of smoothness. Fine details and small features may require additional post-processing to achieve desired surface quality.

Traditional Injection Molding: Injection molding generally produces parts with high surface quality and consistency. The process allows for precise control over the surface finish, texture, and overall part quality.

In summary, 3D printing offers design flexibility, customization, and rapid prototyping capabilities, making it suitable for small-scale production and complex geometries. Traditional injection molding, on the other hand, excels in high-volume production, provides cost efficiency, and offers a wider range of material options. The choice between the two methods depends on factors such as production volume, design complexity, time constraints, and specific project requirement